-

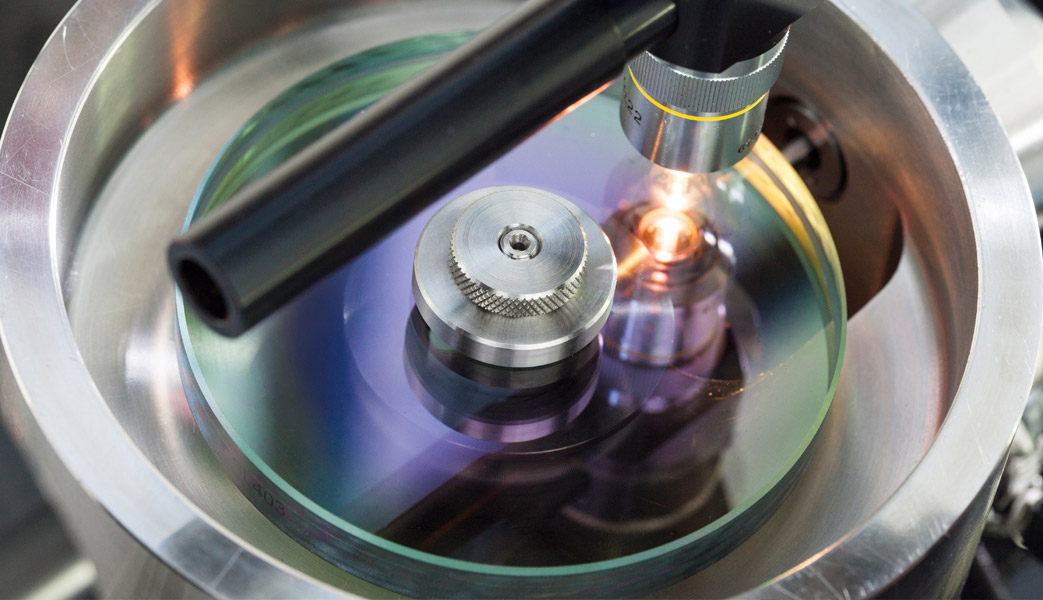

The EHL System measures lubricant film thickness by optical interferometry. A lubricated contact is created by loading and rolling a reflective steel ball against the flat surface of a transparent disc.

The EHL System measures lubricant film thickness by optical interferometry. A lubricated contact is created by loading and rolling a reflective steel ball against the flat surface of a transparent disc.

-

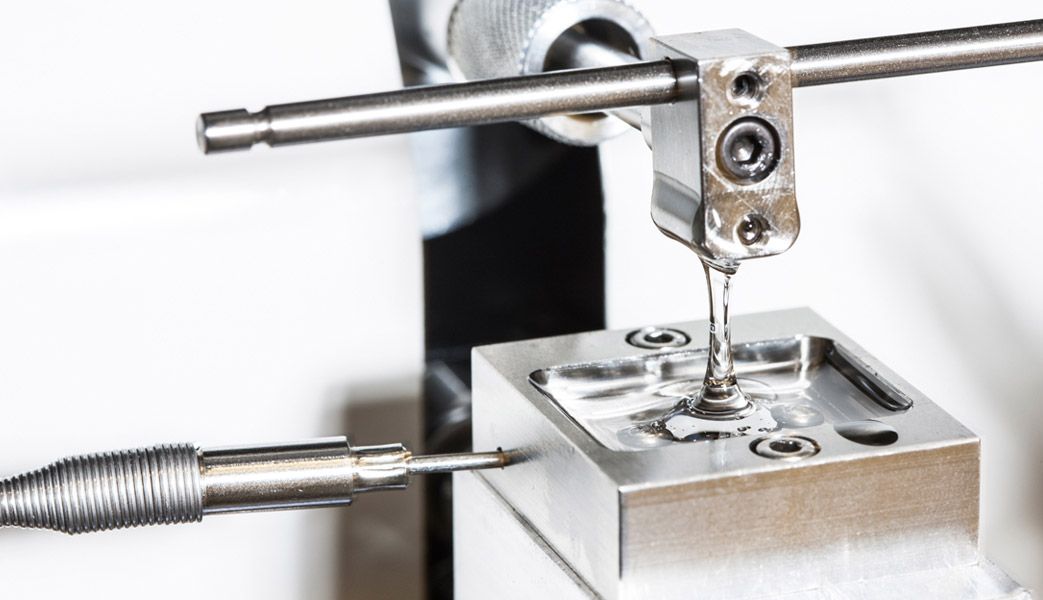

Pure sliding friction tests are carried out in a high frequency reciprocating rig. HFRR is the standard test apparatus for diesel fuel lubricity and is widely used to measure wear and friction properties of lubricants.

Pure sliding friction tests are carried out in a high frequency reciprocating rig. HFRR is the standard test apparatus for diesel fuel lubricity and is widely used to measure wear and friction properties of lubricants.

-

The Mini-Traction-Machine offers a high-end screening test method for measuring friction and wear behaviour of lubricants in a mixed sliding-rolling contact. As a highly versatile test rig, MTM enables testing at any possible slide-roll ratio at constant or variable speed.

The Mini-Traction-Machine offers a high-end screening test method for measuring friction and wear behaviour of lubricants in a mixed sliding-rolling contact. As a highly versatile test rig, MTM enables testing at any possible slide-roll ratio at constant or variable speed.

-

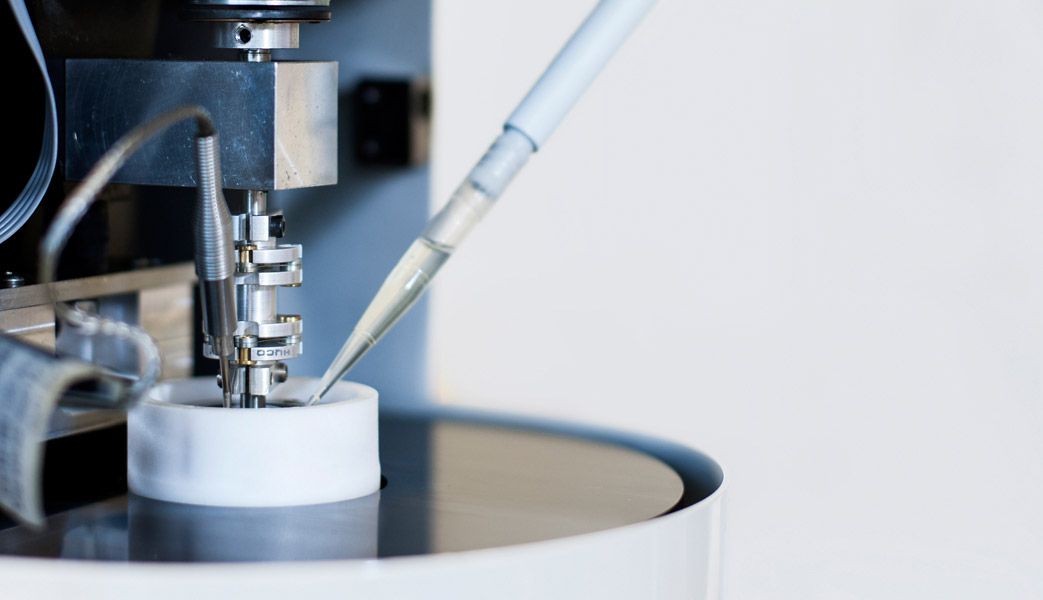

Atomic Force Microscope is a high resolution scanning probe microscope that enables looking at rubbing and other surfaces at the nanoscale.

Atomic Force Microscope is a high resolution scanning probe microscope that enables looking at rubbing and other surfaces at the nanoscale.

-

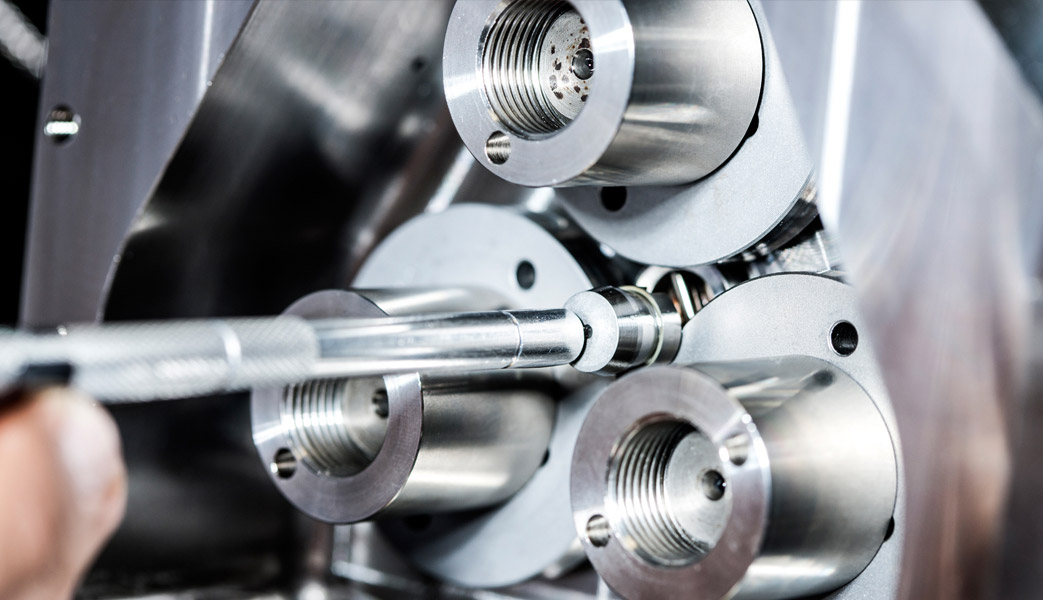

The MPR System is a three-contact disc machine containing three 'counter face‘ rings with a smaller diameter roller located in the middle that is in contact with all the rings. The Micropitting rig and test specimens have been designed to reproduce the lubricated contact conditions which can lead to either micro- or macro-pitting.

The MPR System is a three-contact disc machine containing three 'counter face‘ rings with a smaller diameter roller located in the middle that is in contact with all the rings. The Micropitting rig and test specimens have been designed to reproduce the lubricated contact conditions which can lead to either micro- or macro-pitting.

-

Ultra Shear Viscometer enables accurate measurement of dynamic viscosity at very high shear rates. The viscosity measurements can be carried out over a shear rate ranging from 106 s-1 to 107 s-1 and at temperatures between 40 °C and 150 °C.

Ultra Shear Viscometer enables accurate measurement of dynamic viscosity at very high shear rates. The viscosity measurements can be carried out over a shear rate ranging from 106 s-1 to 107 s-1 and at temperatures between 40 °C and 150 °C.

-

3D optical non-contact profiling system applying dual-LED illumination source for advanced nanometer surface metrology. Surface topography characterization for R&D, process control, wear, failure analysis, and monitoring. Routinely used for 2D and 3D topography data analysis and visualization.

3D optical non-contact profiling system applying dual-LED illumination source for advanced nanometer surface metrology. Surface topography characterization for R&D, process control, wear, failure analysis, and monitoring. Routinely used for 2D and 3D topography data analysis and visualization.