HIGH END TECHNOLOGY TEST EQUIPMENT

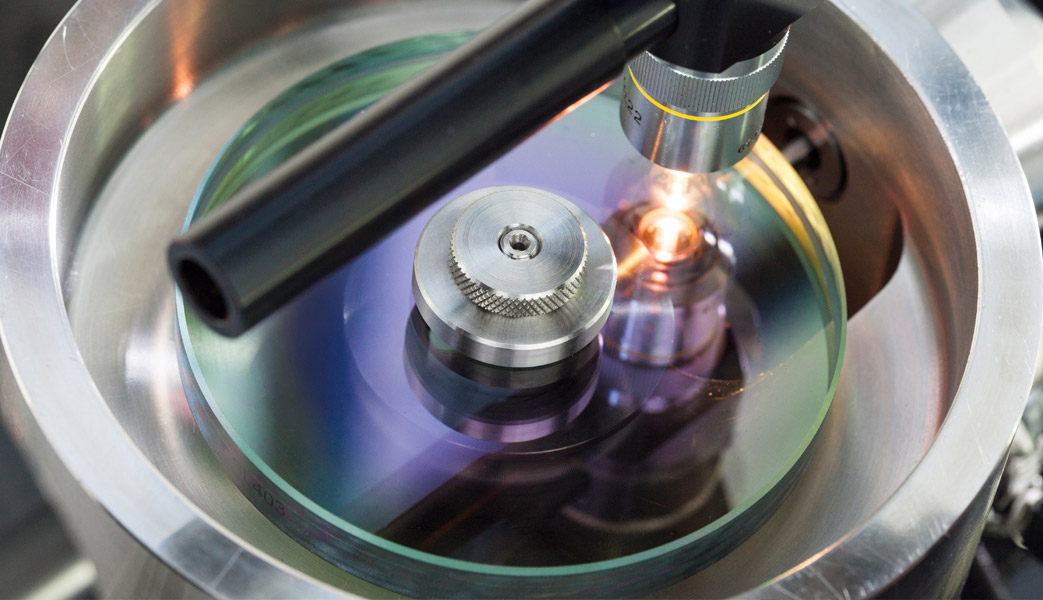

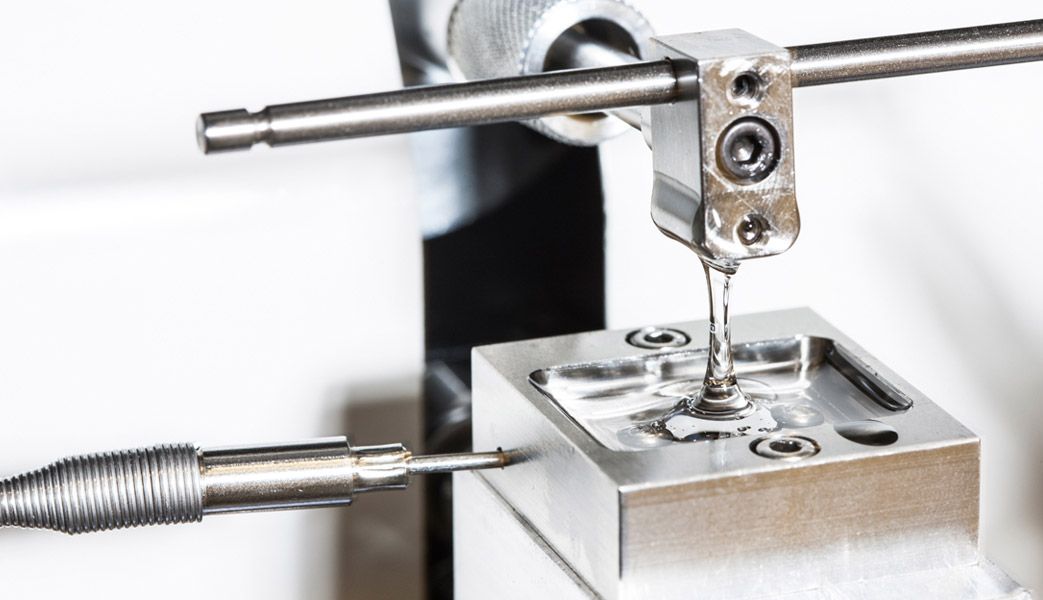

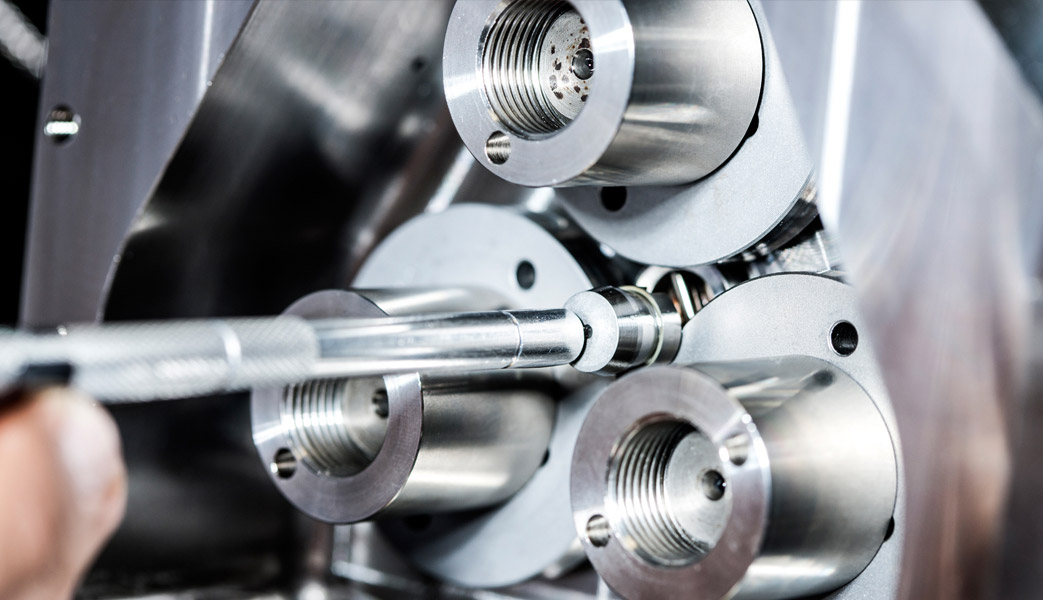

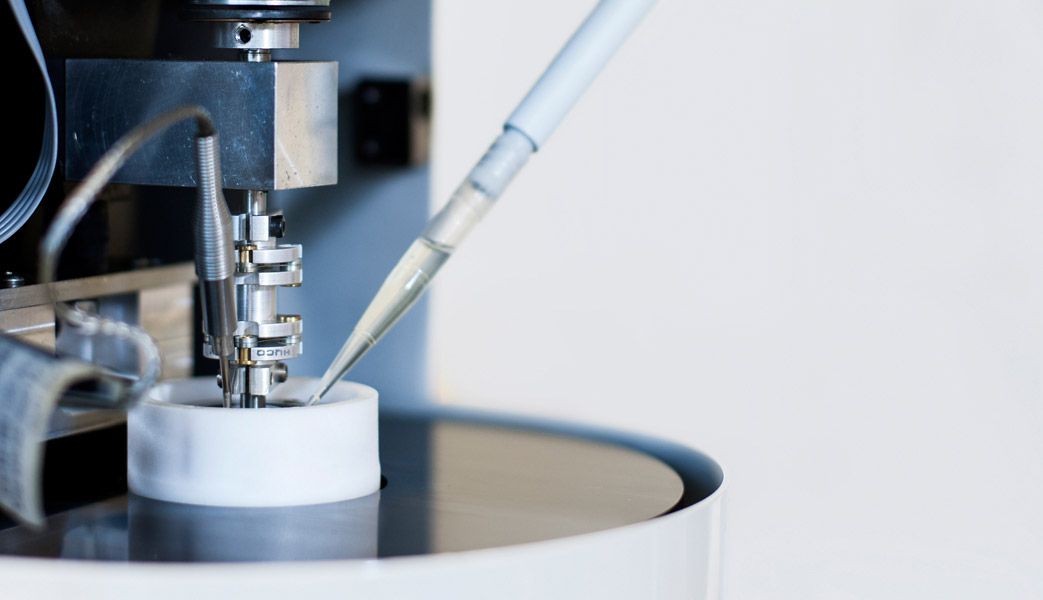

We pride ourselves on our laboratory, which is the heart of POWERTRIB. This is where we apply the latest test methods using high-quality tribology testing equipment. Our research stands out as our analyses go into more detail and depth than usually. Owing to the large number of high-technology test machines in our laboratory, we are leaders in the field of test method development.

We constantly subject all our instruments to stringent tests in order to ensure precise results. Our partner PCS Instruments, leading producer of test equipment worldwide, develops high-end technology in the field of tribology. Using this technology and our profound know-how, we examine extensive tribology data.